About Shoufu

Purchase stainless steel. We would be your best friend and partner.

Our company sells high-quality stainless steel materials, steel plates, steel coils, steel strips, steel pipes, steel rods, and other products from steel mills such as Taiyuan Iron and Steel Group, Baosteel, Zhangpu, and Jiuquan. We can also customize the required materials according to customer requirements. We are widely used as materials in industries such as automobiles, electricity, petrochemicals, shipbuilding, aerospace, and construction.

0

Years Of Experience

1180

Factory Floor Area

100

Professional Skill Worker

We Keep Working Online, Get In Touch.

Hot-sale product

We look forward to be your reliable and quality partner!

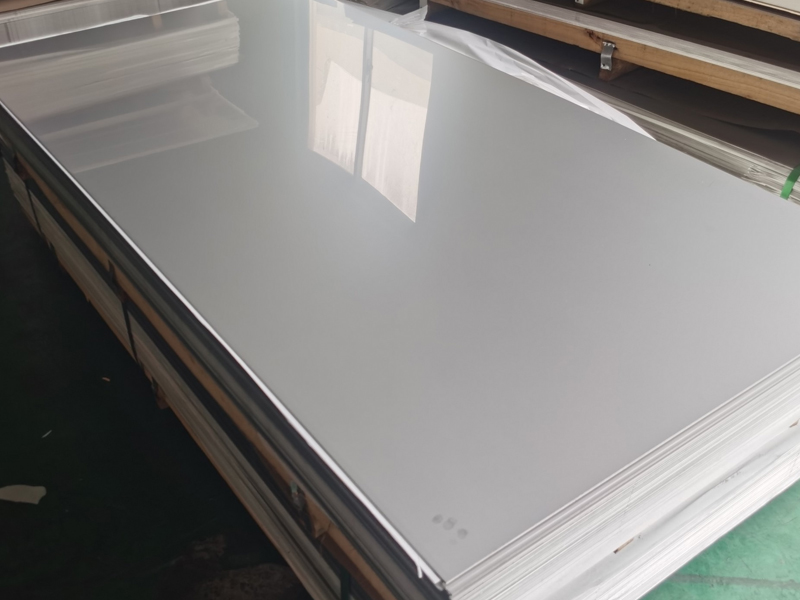

Cold-Roll Steel SheetsStainless Steel Sheet/Plate

Cold-Roll Steel SheetsStainless Steel Sheet/Plate 316L Stainless steel sheet/plateStainless Steel Sheet/Plate

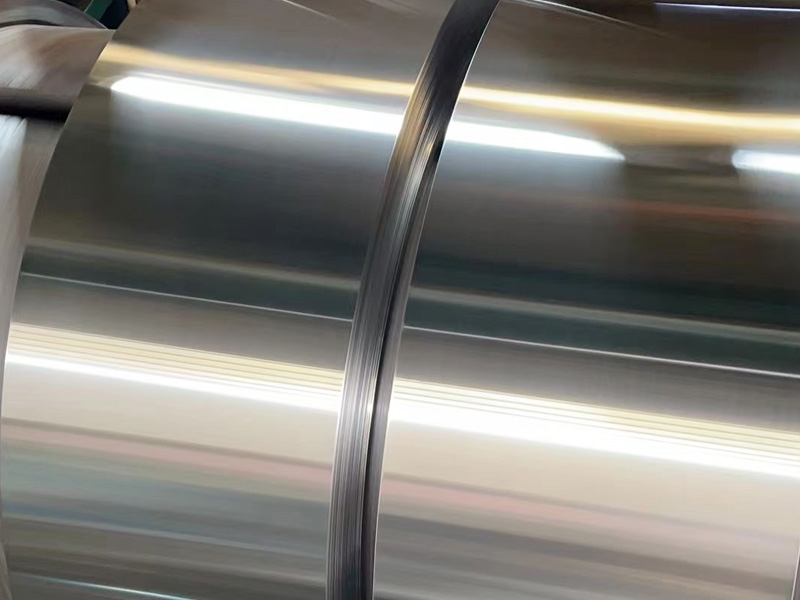

316L Stainless steel sheet/plateStainless Steel Sheet/Plate 321 Stainless steel coilStainless Steel Coil

321 Stainless steel coilStainless Steel Coil 304 Stainless steel coilStainless Steel Coil

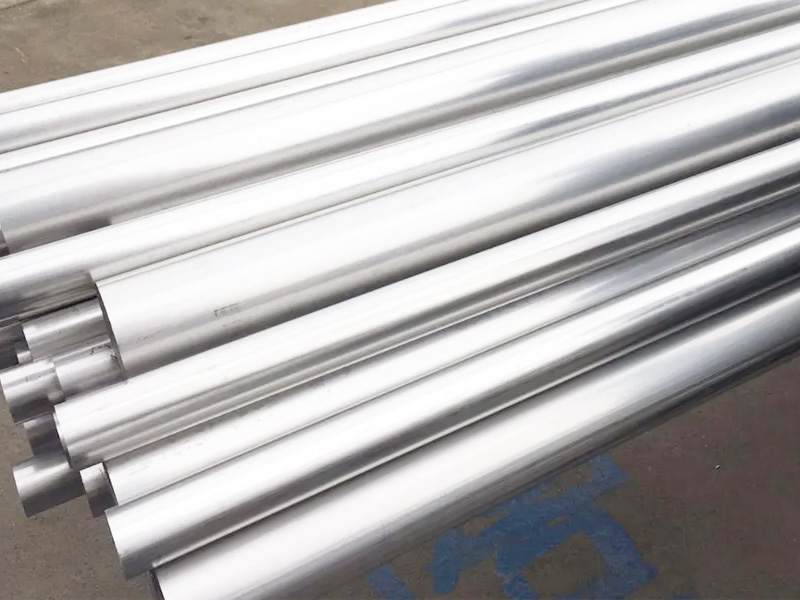

304 Stainless steel coilStainless Steel Coil 304 Stainless Steel BarStainless Steel Bar

304 Stainless Steel BarStainless Steel Bar 304L Stainless steel stripStainless Steel Strip

304L Stainless steel stripStainless Steel Strip 310S Stainless steel stripStainless Steel Strip

310S Stainless steel stripStainless Steel Strip 316 Stainless steel pipe/tubeStainless Steel Pipe/Tube

316 Stainless steel pipe/tubeStainless Steel Pipe/Tube

Product equipment

We look forward to be your reliable and quality partner!

WHY

CHOOSE US

We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

01

We are an efficient team,providing you with professional service for high quality and efficiency.

03

24 hours online .

only to give you the best service

02

We provide products with competitive price based on good quality, and we arrange each shipment on time.

04

We will try our best to meet customers requirements and provide best after sale services.

Latest News

We look forward to be your reliable and quality partner!

Some important knowledge about stainless steel coils2023-07-05Stainless steel for beginners, how to identify different stainless steel is very important.

Some important knowledge about stainless steel coils2023-07-05Stainless steel for beginners, how to identify different stainless steel is very important. Physical properties of stainless steel strip2023-07-05Specific heat capacity: with the change of temperature, the specific heat capacity will change.

Physical properties of stainless steel strip2023-07-05Specific heat capacity: with the change of temperature, the specific heat capacity will change. What are the specifications of stainless steel profiles?2023-07-05In engineering construction, people often use a kind of building material - stainless steel profile.

What are the specifications of stainless steel profiles?2023-07-05In engineering construction, people often use a kind of building material - stainless steel profile.

WANT TO LEARN MORE

Thank you for your interests in us. Please feel free to submit your inquiry information to us. our sales manager will contact with you as soon as possible.